Assessment of Pregelatinized Corn Starch (Zea mays L.) as an Excipient in Pharmaceutical Preparations

Downloads

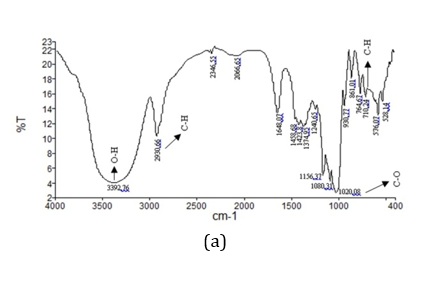

Indonesia has a large potential for corn starch production since corn is one of the most widely grown foodstuffs. In addition to being a food ingredient, corn also has the potential as an excipient in pharmaceutical preparations because of its very high starch content, which is 72-73% of the total weight. In tablet preparations, starch is widely used as a binder, disintegrant, and filler. One of the weaknesses of starch is its poor mechanical properties. Pregelatinization is one of the physical modification methods that can improve the mechanical properties of corn starch. The purpose of this study was to determine the effect of pregelatinized corn starch on the physical, chemical, and mechanical properties. Pregelatinized corn starch was prepared as follows: 250 g of starch was added to 250 mL of distilled water, heated at 70°C for 20 minutes, stirred until thick, dried in a drying cabinet at 60°C for 24 hours, and sieved through a 16/18 mesh sieve. The starch was tested for its physical, chemical, and mechanical properties. The results showed that the pregelatinized corn starch base on physical, microscopic and functional properties better than native corn starch in the formulation composition or process.

Downloads

Anisa S, Dalimunthe GI, Lubis MS, Yuniarti R. Isolasi Amilopektin dari Pati Jagung (Zea Mays L) yang Berpotensi Sebagai Film Coated Pada Tablet. FARMASAINKES: Jurnal Farmasi, Sains, dan Kesehatan. 2023;3(1):51-57. doi: 10.32696/farmasainkes.v3i1.2377.

Li D, Zhuang B, Wang X, Wu Z, Wei W, Aladejana JT, et al. Chitosan used as a specific coupling agent to modify starch in preparation of adhesive film. Journal of Cleaner Production. 2020;277(22):123210. doi: 10.1016/j.jclepro.2020.123210.

Wang Q, Li L, Zheng X. A review of milling damaged starch: generation, measurement, functionality and its effect on starch-based food systems. Food Chemistry. 2020;315:126267. doi: 10.1016/j.foodchem.2020.126267.

Hartesi B, Meirista I, Mariska RP, Soyata A, Fitria F, Lestari O. Modifikasi Pati Beras Ketan Putih Sebagai Pengisi Pada Pembuatan Tablet Kempa Langsung. Majalah Farmasetika. 2022;8(1):70-94. doi:10.24198/mfarmasetika.v7i4.40370.

Li D, Zhuang B, Wang X, Wu Z, Wei W, Aladejana JT, et al. Chitosan used as a specific coupling agent to modify starch in preparation of adhesive film. Journal of Cleaner Production. 2020;277:1-8. doi: 10.1016/j.jclepro.2020.123210.

Anggraeni W, Ratih H, Anis N, Ramadan A, Kemampuan Pati Pregelatinasi Buah Sukun (Artocarpus altilis (Parkinson ex F.A.Zorn) Fosberg) sebagai Bahan Penghancur pada Tablet Eritromisin Stearat, PHARMACY Jurnal Farmasi Indonesia (Pharmaceutical Journal of Indonesia). 2021;18(2):402-412. doi: 10.30595/pharmacy.v18i2.9125.

Rahmawati TE, Cahyani IM, Munisih S. Karakterisasi Pati Bonggol Pisang Kepok Kuning (Musa paradisiaca L.) sebagai Bahan Tambahan Sediaan Farmasi. Jurnal Sains Dan Kesehatan. 2023;5(2):100–108. doi: 10.30872/jsk.v5i2.p100-108.

Diniyah N, Subagio A, Sari RNL, Yuwana N. Sifat Fisikokimia Dan Fungsional Pati dari Mocaf (Modified Cassava Flour) Varietas Kaspro Dan Cimanggu. Jurnal Penelitian Pascapanen Pertanian. 2019;15(2):80-90. doi: 10.21082/jpasca.v15n2.2018.80-90.

U.S. Pharmacopeia. The United States pharmacopoeia: The national formulary. United States Pharmacopoeial Convention. 2023.

Kemenkes RI. Farmakope Indonesia. Edisi VI. Jakarta: Kementerian Kesehatan Republik Indonesia. 2020.

Sulaiman TNS, Wahyono, Bestari AN, Aziza FN. Preparation and Characterization of Pregelatinized Sago Starch (PSS) from Native Sago Starch (NSS) (Metroxylon sp.) and its Evaluation as Tablet Disintegrant and Filler-Binder on Direct Compression Tablet. Indonesian Journal of Pharmacy, 2022;33(2):251-260. doi: 10.22146/ijp.3543.

Hartesi B, Andriani L, Anggresani L, Whinata MB, Haflin H. Modifikasi pati kentang secara pregelatinasi dengan perbandingan pati dan air (1: 1,25). Riset Informasi Kesehatan, 2020;9(2):149-162. doi:10.30644/rik.v9i2.431.

Sastrohamidjojo H. Dasar-Dasar Spektrokopi. Gadjah Mada University Press. Yogyakarta. 2013.

Ma H, Liu M, Liang Y, Zheng X, Sun L, Dang W, et al. Research progress on properties of pre-gelatinized starch and its application in wheat flour products. Grain & Oil Science and Technology. 2022;5(2):87-97. doi: 10.1016/j.gaost.2022.01.001.

Badan Standarisasi Nasional. Pati Jagung (SNI 8523:2018). Badan Standarisasi Nasional. Jakarta. 2018.

Jia R, Cui C, Gao L, Qin Y, Ji N, Dai L, et al. A review of starch swelling behavior: Its mechanism, determination methods, influencing factors, and influence on food quality. Carbohydrate Polymers. 2023;321:1-24. doi: 10.1016/j.carbpol.2023.121260.

Fitriani S. Daya pembengkakan serta sifat pasta dan termal pati sagu, pati beras dan pati ubi kayu. Jurnal Ilmiah Teknologi Dan Industri Pangan UNISRI. 2018;3(1):41–48. doi: 10.33061/jitipari.v3i1.1987 .

Rahmawati TE, Siswanto A, Djalil AD. Optimization of Fast Disintegrating Tablets Diphenhydramine HCl using Co-process of Cross-link Yellow Kepok Banana Starch, Crospovidone, and Microcrystalline Cellulose. Jurnal Ilmu Kefarmasian Indonesia. 2023;21(2):231-238. doi: 10.35814/jifi.v21i2.1406.

Wang B, Gao W, Kang X, Dong Y, Liu P, Yan S, et al. Structural changes in corn starch granules treated at different temperatures. Food Hydrocolloids. 2021;(118):1-7. doi: 10.1016/j.foodhyd.2021.106760.

Ma H, Liu M, Liang Y, Zheng X, Sun L, Dang W, et al. Research progress on properties of pre-gelatinized starch and its application in wheat flour products. Grain & Oil Science and Technology. 2022;(5):87–97. doi: 10.1016/j.gaost.2022.01.001.

Lobubun NA, Chabib L. Formulasi Granul Effervescent Ekstrak Aseton Rimpang Kencur (Kaempferia Galanga L.) dengan Variasi Konsentrasi Polivinilpirolidon. Journal of Pharmaceutical and Health Research. 2022;3(3):139–149. doi: 10.47065/jharma.v3i3.2922.

Copyright (c) 2025 Jurnal Kefarmasian Indonesia

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.